CoLab’s AutoReview tool is still in early access, but thousands of engineers have signed up for the waitlist. Here's why.

Engineers are still humans—for now—but AI is ready to check their work.

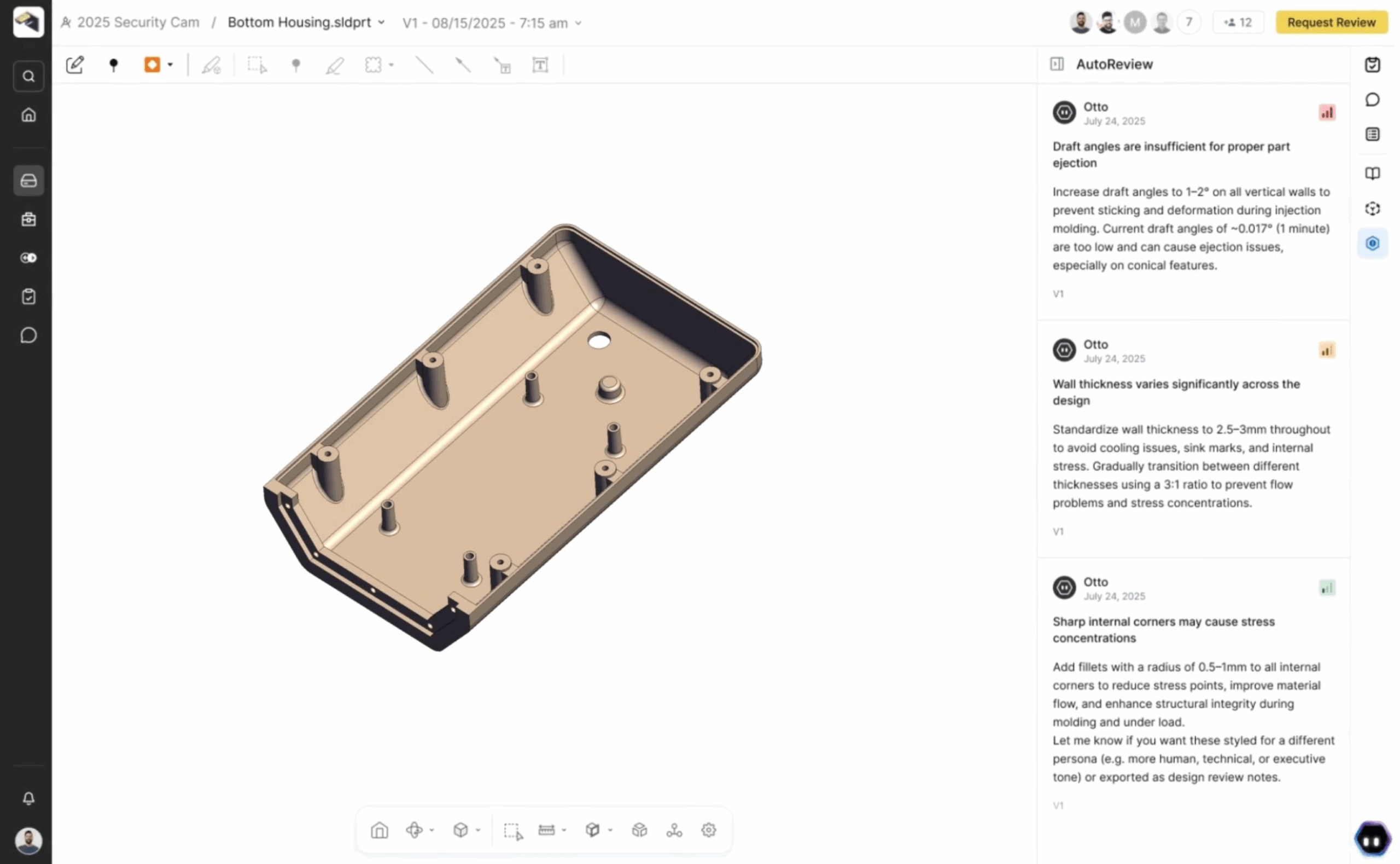

Newfoundland-based CoLab has released AutoReview, an AI tool that the developer says can automatically find errors in engineering files and suggest fixes. By ingesting historical data and company standards, AutoReview also learns from past mistakes to provide tailored recommendations.

“We see this being the first cut in every review. Catch all the low hanging fruit, identify design flaws, find things that you might miss, and suggest optimizations,” Adam Keating, co-founder and CEO of CoLab, told Engineering.com.

With tens of thousands of names on the AutoReview waitlist, the AI tool is already exciting engineers. Here’s everything you should know about CoLab and its new AI.

CoLab and the Design Engagement System

CoLab was founded in 2018 by Keating and co-founder Jeremy Andrews. Frustrated by what they saw as dated and inadequate design software, the pair of mechanical engineers set out to develop better collaboration and decision-making tools for engineering teams.

The result was CoLab’s Design Engagement System, or DES, a cloud-based platform for design review and collaboration. The CoLab DES augments—and integrates with—PLM systems including Siemens Teamcenter, PTC Windchill, SolidWorks PDM and more.

Keating described the DES as CoLab’s bread and butter. In AutoReview, the company may have hit upon peanut butter and jelly.

AutoReview as a peer and mentor

AutoReview marks the beginning of a second chapter for CoLab, Keating said. It’s a new product, but it’s tightly entwined with the company’s existing DES.

“We realized probably two years ago that we were sitting on an interesting set of data, which is the customers’ knowledge data,” Keating said.

While PLM systems store the final outcomes of design decisions, CoLab’s DES was designed to capture exactly how those decisions were made. By plugging that information into a custom-made machine learning model, CoLab thought they could uncover valuable insight to inform future design reviews.

That idea became one aspect of the AutoReview tool that CoLab has now released.

Lessons-learned AutoReview, as Keating calls it, relies heavily on existing customer data. It analyzes geometry, metadata, text and images to find common problems and provide custom feedback. Keating says beta users have described it as “a mentor over the shoulder.”

“That’s probably the most common feedback, was that it was really helpful for surfacing something, and particularly for junior people,” Keating said.

The other aspect of AutoReview is what Keating refers to as a peer-checker.

“The peer-checker is exactly what it sounds like: 2D/3D review automated by AI,” Keating said. “You put a file in, tag a checklist against it, and it will ultimately go in and red-line the file for you, or annotate the 3D model.”

Taken as a whole, AutoReview essentially acts as an artificial user of the CoLab DES, performing a first-pass design review that users can act on if needed. It can identify data inconsistencies, missing information, standards violations, potential manufacturing problems and other design flaws, according to CoLab.

How can you access AutoReview?

If you’re intrigued by AutoReview, you’re not alone. Keating says CoLab has been inundated by engineers signing up for the early access waitlist, which has stretched to around 27,000 names.

“Our hope is that by end of this quarter, we’re a little closer to having the resources we need to just kind of free-flow onboard people,” Keating said.

It’s not as easy as merely turning AutoReview on for every DES user, Keating added. “We’re trying to be coaching the first number of customers until we feel confident that we just let them go with no training wheels.”

When it’s generally available, AutoReview will be licensed through an AI credit system, according to Keating. CoLab’s DES is offered in multiple subscription tiers for different numbers of users, and additional partner tokens can be purchased to provide access to suppliers, customers and other external groups.

The future of AutoReview

Despite the popular demand, AutoReview can only succeed with engineers if it actually works. So how well does it work?

In developing AutoReview, CoLab’s initial goal was for half of the AI’s suggestions to be undeniably worthwhile, according to Keating. Through model improvement and human feedback, the company expects AutoReview to get better from there.

“The goal, really long term, is that we can get this like 80 – 90% of the feedback you want to integrate basically immediately,” Keating said. “We’re iterating incredibly hard. It’s number one priority for us right now.”

At the moment, AutoReview’s efficacy varies depending on the use case.

“We’re being really clear to customers [that] we’re not trying to sell them everything right now,” Keating said. “It’s really for drawings in particular, component level, DFM, across five or six manufacturing processes. If you go outside of that, it can vary depending how complex the thing you are doing is.”

Assuming AutoReview achieves the hit rate CoLab hopes for, the AI tool has natural extensions. If AI can automatically flag design errors, perhaps one day it could automatically fix them as well. It could also potentially integrate with external engineering tools to run simulations on the design.

Keating didn’t provide specifics, but he made it clear CoLab has big plans for the future.

“Down the road there’s a whole suite of other products that build into this new operating system,” he said. “We’re starting to see an opportunity to stitch some of the things we’re doing together and then go deeper into specific verticals of use cases for customers.”

AutoReview still needs to prove itself, but it’s clear why engineering teams are excited about it. Mistakes have always been a learning opportunity. Now, they’re a machine learning opportunity too.